A while back, I received a question that asked about the best way to sharpen stainless steel knives, a common problem, especially considering how much easier it is to sharpen carbon steel than stainless steel. Well, it seems a lot of you benefited from that article, and as a result, I thought it’d be a good idea to do a very similar article detailing how one can sharpen ceramic blade knives, since those are even more tricky to sharpen.

Ceramic is basically the black sheep material of the cutlery industry, and whilst many do like using it in the kitchen, I’m not personally all that fond of it myself. If you haven’t jumped the gun and purchased some ceramic knives yet, but are considering it, I’d suggest against it. I describe why in this article, that discusses the pros and cons of using a ceramic blade knife over a steel blade knife.

First: Yes, Ceramic Knives Do Eventually Get Dull

Over the past few years we have been swamped with advertising that equates ceramic as the viable alternative to steel, especially for kitchen knives. Ceramic has been promoted with the incredibly silly marketing promise that it never gets dull: obviously we know this is nonsense. Ceramic (as used in cutlery) is primarily made of Zirconia (zirconium dioxide), which, while it does have some advantages, is by no means a wonder material – a fact anyone who has used ceramic knives firsthand knows.

It’s Tricky Sharpening Ceramic Knives: Here’s Why

The main crux of the problem is that, while ceramic looks and feels great, it’s also incredibly brittle, and thus much easier to break than any steel knife you could imagine. With that in mind, when it comes to sharpening a ceramic knife, you absolutely must keep in mind that under no circumstances should you exert too much pressure on the blade laterally. Or it will literally snap in half. I’ll explain this in further detail below, but it’s the one rule to sharpening ceramic you’ll need to remember.

For those who have sharpened blades besides those made of ceramic, you need to keep this rule in mind particularly because you’ll likely be looking for some kind of spring or feedback – like with all the steel knives you’ve sharpened in the past. Ceramic does not give when pressure is applied, much like glass, so don’t expect any level of spring or feedback with these, period. Also, when sharpening ceramic, unlike sharpening steel no burr will be formed because ceramic is not a ductile material. As a result, edge sharpness will ultimately be dependent on the final grit of the edge and how precise your movements are.

What You Should Never Do When Sharpening Ceramic Knives

Now on to explaining that single most important rule further. The picture below is the perfect example of what you should never do. As I said, you shouldn’t be applying too much pressure on the blade laterally, and with this kind of positioning, you may think you are not applying much at all, but it takes just a touch too much and snap – there goes your nearly new ceramic knife. Positioning your hands this way is basically inviting risk – don’t do it.

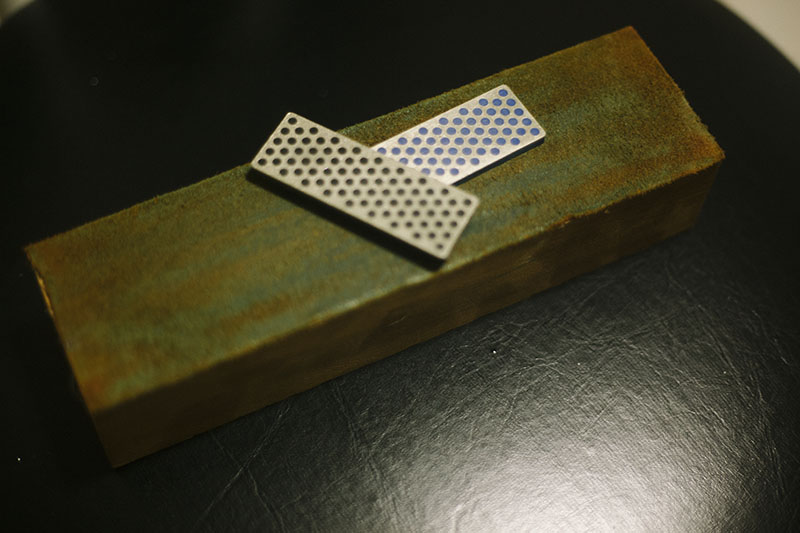

DMT Diamond Whetstone – Amazon

DMT Diamond Whetstone – Amazon

Instead, What to Always Do When Sharpening Ceramic Knives

What I suggest doing instead is positioning your knife with both hands, like in the picture below. Apply light force consistently with your fingers, all the while supporting the blade. Make absolute sure that zero flex occurs, and this will really limit any chance of inadvertent snapping. Needless to say, it’s much easier to control the blade when you’re holding it in your hands this way.

It technically makes no tangible difference if you move your hands up or down when sharpening. I myself favor moving my hands in a downward motion only, but that’s just personal preference. You can go up and down, only up, or only down, and it won’t matter at all to the final result – the knife will get sharp.

Nice and smooth movements and very slight pressure is basically all there is to having good technique. I found that stropping is technically viable, but the amount of effort and care one would have to put into get a mirror polish is simply not worth (it my opinion). I’d definitely stick to the positioning below.

Tools You Can Use to Sharpen Ceramic Knives

When it comes to sharpening tools, I would heavily recommend sticking with diamond stones.

You can technically use other types of knife sharpeners, but diamonds are harder and thus will require far less work to remove material. This means that you can restore your knife’s sharpness of your ceramic blade quickly and efficiently, and you won’t be tempted to apply more force to “speed things along” so to speak.

I suggest using 200 grit diamond if there are large chips, and then moving on to 600, 1000, and finally 1500.

Many people use traditional waterstones (like these) to sharpen ceramic, and whilst yes, traditional abrasives like sandpaper and waterstones will work, I couldn’t recommend them over diamond stones.

If you feel more comfortable using a proper knife sharpener over loose diamond stones, you’ll want to get your hands on both the Spyderco Sharpmaker and the diamond stone addons.

Why? If you just get the Spyderco Sharpmaker and try to use it out of box, you’re unfortunately probably going to snap the ceramic blade of the knife while doing your best to try getting your knife’s edge sharp.

Even though ceramic is definitely not my cup of tea for cutlery, I will say that edge retention will be far above average – the blade will certainly stay sharp for quite a long time so long as proper precautions are maintained when handling the knife. The appeal of a no maintenance knife is very attractive for a lot of people, so if you’re okay with the fragility aspect of ceramic knives, don’t let difficulty sharpening deter you. Grab a diamond stone and give it a shot. You’ll be a pro in no time.

As always, let me know if you have any further questions in the comments!

I bought a new ceramic knife for $1 at Bargain Bins today. I figured sharpening it would be about like you described it — very little side pressure and diamond stones. I have a set of three from Harbor Freight but don’t remember what grit they are. And HF didn’t do me the courtesy of labelling them, it seems.

Like you, I’m emotionally attached to the old carbon steel and Case chrome vanadium blades for their ease of sharpening and edge retention. I despise confounded stainless steel. Thanks for the good info, bro.

And, uh, stropping never was about polishing the blade. It was to straighten the edge that had rolled over between sharpenings. That info is courtesy of my childhood barber and my dad. If your skin on the palm of your hand is thick and dry enough, you can strop a pocket knife there. I do it all the time. My chiropractor told me that about 40 years ago.

Modern steels have such high rockwell that a strop loaded with a cutting compound is there just for adding a final high polish bevel. Historically, yes, one would stop or hone to straighten the edge when it deviated through use.

I bought a ceramic paring knife at a thrift store. I have a tri Stone set up. However, I only use the natural Arkansas Stone with cutting oil. I read up on it before I started doing anyting. Thanks to your article I realized how fragile the blade is. And I love the process of sharpening knives with stones. Especially natural stones. It was the way I was taught when I was very young. It fills me with pride when people say, “that is a wicked sharp knife.”

But I’m still having trouble getting that edge on my paring knife. It’s always best in the diamond. Thanks for the tip.

You can sharpen ceramic knives. I have a Kyocera” Diamant Electrical Knife Sharpener and it works. It isn’t cheap but then neither are good ceramic knives.

Roommate had a nickel allergy, and was having trouble finding steel knives that had none in them. One of the handful of times I have been in a Kohl’s, I looked to my side while in line…ceramic knives. Well, I guess it’s worth a shot. Bought 2, total was maybe $35. She used them both, and SEEMED to like them. I started using them too. When she moved out, she had taken one and left the other. I’ve been using the one she left for I think about 3 years now. There is some minor chipping on the edge. Probably from putting it in the dish strainer to dry and bumping other things. Still cuts like a champ though.

So, I guess if nothing else they are good for people that have allergies.

A worthy point Ron, thanks for sharing.

One more nice thing that most may not need to consider is, guys (like me) who fish a lot in salt water, usually fight with bait knives that usually stay on the boat, will in time, corrode. The dollar store ceramic knives are the ticket for this.

Thanks.

I bought into the hype several years ago and bought a set of four Kitchenaid ceramic knives—a chef’s knife, santoku knife, and two paring knives. First off, I only ever used the chef’s knife and larger pairing knife, and could have used a boning knife, for which ceramic is hopelessly suited. Mainly, though, they were fairly good “disposable” knives, and after a few years, I found out I’d really like a knife I can sharpen.

So, I find myself buying a midrange pair of knives: a chef’s knife and a paring knife, along with a cheapie chef’s knife to practice sharpening, honing, etc., as I learn how to treat a knife properly after all these years. Interestingly, I’m spending about as much on stones and a honing rod as on the knives.

Yup, its a real addiction. I have so many sharpening set ups, waterstones etc. its kinda crazy.

Try a Forschner/Victornox knife. The Swedish steel they use is outstanding. Easy to sharpen, yet holds edge a good long time. They make a fantastic boning knife!

A new comment caused this 2015 post to circulate through my inbox, and re-reading it brought up a couple of issues I chose not to comment on originally, but the re-read changed my mind.

‘I recommend diamond stones for sharpening…’

(this is usually the place someone would insert, “Not being a smart-ass, here, but…’ before making a statement like I’m about to. Instead, my prefacing comment is, “BEING a smart-ass…”‘

Safe recommendation, X, considering diamond is the ONLY readily available substance which CAN sharpen ceramic.

Sharpening is an abrasive process, no different than sanding wood before applying finish, polishing metal to acheive a mirror image or sanding the body of a car to create a ripple free paint job.

The abrasion process involves taking away progressively smaller, and smaller particles of whatever material being abraded until the scratches left in the material are not visible to the naked eye.

The only difference when sharpening a knife is the end result, which in a knife, is a sharp edge. Typically, in metal working, removing sharp edges is one goal; eliminating potential sources of cuts when using the item.

Gaining a sharp edge is a matter of shaping the edge until the edge is as close to prefectly straight, (when looking at the edge longitudinally), as possible and the molecules are minute enough along that straight edge to acheive the desired sharpness.

The absolute sharpest edge possible would be when the edge is abraded until it is only one molecule wide.

For abrasion of any material to take place, the abrasive must be harder than the material being abraded. It’s only common sense; an abrasive softer than the material being abraded won’t do shit!

To make the point, take an example to the extreme: you have an exotic, multiple alloy, space-age, alien-tech knife blade needing a fresh edge, (don’t question why, given it’s heritage, why would it ever be dull? OK, for you purists, you needed to cut chain, and that’s all you had available… can we move on, now?)

If you use anything softer than the knife blade, you will achive nothing. Try using plastic, aluminum, even some steel.

That’s why sandpaper is aluminum oxide, or some other mineral hard enough to abrade steel alloys. That is why diamond is used to sharpen ceramic, since diamond is the only substance, readily available, and useable as an abrasive, which will abrade ceramic.

Ceramic is a fired clay, not unlike pottery. Mixing the zirconium with other materials, blades and other items are shaped, then fired. Ceramic is starting to see inroads in other areas than knives: I have a phenomenal $2.00 eBay clam shell cutter which is also safe enough a child could it, and not cut themselves. I am also seeing high speed grinder burrs being made from ceramic, to name two.

If it won’t scratch ceramic, it won’t sharpen it!

Second re-read item:

‘blade flex you are familiar with…’

If you are applying enough pressure to visually or tactually observe blade flex, (in other words, enough to flex and break a ceramic blade), you are pressing too damn hard.

Sharpening ANYTHING is a gentle process, the edge should float across the sharpening device, with NO MORE pressure than it takes to cause abrasion.

You don’t gain anything by mashing an edge onto the stone while sharpening, and in the case of using diamond ‘stones’, you will actually damage them. (If you are one of those condenming diamond stones because, ‘they wear out too quick.’, then you are applying WAY too much pressure.

I know DMT says there coarsest ‘stone’ is equivalent to a file or grinding stone, (can’t recall which, right now), but the cannot REPLACE a file or grinding stone, so don’t treat diamond sharpeners like a file or bench grinder!

On a side note, when a diamond ‘stone’ is new, you can ‘feel the abrasion’on the working face. According to DMT, who makes diamond sharpeners, this roughness will wear off with use, but does NOT mean the sharpener is ruined, or wore out. It will continue to abrade, as normal.

Excess pressure WILL cause the diamond abrasive to wear off, and the ‘stones’ WILL be riuned, though.

When I was taught to sharpen, the old-timer had me learn by prompting me to sharpen an edge using the least amount of pressure possible, while still abrading the material. He also had me use a jeweler’s loupe for viewing the edge from before I started, until I finished.

It is a useful, and very valuable exercise, even if you have been sharpening for 50+ years, like I have. If you are new to sharpening, it is even more valuable. (an inexpensive, good loupe can be bought on eBay for less than $10.00, and make great magnifiers for many purposes; worth having one around.)

Hope this helps someone.

GeoD

Good points all in this post. In the Sharpmaker video Sal Glesser said to only use about three pounds of pressure when using the Spyderco ceramic sharpeners. Adding pressure to the blade isn’t going to speed up the process and will most likely end up in a rolled edge.

Great information! Thank you for sharing your knowledge!

Love our ceramic knives for cutting up fresh fruits and vegetables / does not leave the brown oxidation on lettuce for many days- our main reason for buying ceramic was to prevent the browning- my comment is just buy another knife when they get dull? it’ll take years but why chance shards of ceramic if you’re trying to sharpen it ?

My counter-point is that I am simply not comfortable having a tool that requires outright replacement when proper, longterm alternatives exist. Check out a Victorinox Forshner series of knife- the chromium content is high enough to limit or outright eradicate oxidation. Let me know if that works for you!

What about the metal they add for safety so that the ceramic knife is detected by a metal detector… would it affect the oxidation? I own a ceramic knife.

I’ve bought 2 smallish ceramic fruit knives – one cheap and one more expensive. I agree with you – they’re not a patch on steel. The thing I particularly notice is that the blades are so thick, making them less useful. Possibly for something like carving a roast, but definitely not for peeling fruit.

I have 2 kitchen knives I love – fruit or vegetable sizes – one is an old steel (not stainless) which came from my grandmother, and another pair which we got 45 years ago, but were fine Japanese Stainless (Eagleport Miracledge brand). Both are thin bladed and great to use, but do need care and occasional sharpening or touching up with a steel.

Your experiences mirror my own mate, thanks for sharing!

Will something like a knife sharpener on the back of a can opener work well on ceramic knives I love my stainless knifes because I can sharpen them with a hand held knife sharpener by Rubbermaid.

Will it work? Maybe (I assume its a carbide pull through sharpener and in that case- I just don’t know), will it work well? Doubtful. I recommend using diamond stones when sharpening ceramic blades.

No for one of three reasons. It is either carbide and softer than ceramic, it is ceramic and the same, or itbis diamond that is too coarse and will chip the edge.

Thanks for chiming in Derek, perfect summation.

Hi Thomas,I was doing a search for sharpening ceramic knives and this blog popped up.I brought a ceramic knife just to test its durability as compared to my other knives and to save my good knives from being mistreated by my Daughter.Well the time came when i had to repair and resharpen the ceramic knife(tip was chipped).I have Japanese Waterstones of which im no master and i also have the Edge Pro Professional system which I like as it gives me the precise scary sharp edges every time.I have diamond plates 400 and 600 grit which i used on the ceramic knife and i found that the 400 grit was ok to reset and repair but wouldn’t put an edge on it.The 600 grit did put an edge on it but not very sharp.Im waiting for a 1200 grit diamond plate to arrive and hopefully it will achieve the results im after.I will say after years of sharpening steel knives the ceramic was a challenge and found it to be fragile as an everyday kitchen knife.I wouldn’t recommend any one buy ceramic.Steel knives are easier to maintain and more forgiving if mistreated.

Basically my experiences too Nigel, I reckon the 1200 grit plate will help a lot, let me know how it works out and remember to take it slow and easy (consistent angles will create a better edge). Thanks for dropping by mate!

Hi there, there is very little info on carbide and ceramic sharpening on the internet. I have a ceramic knife and carbide blades that simply dont take an edge using the same process as steel. I love hair whittling with supersteels. 10V, S110V, 204p, K390 and ZDP are all easy for me. Hair shaving with any grit honestly. I have a 16 k shapton i will use sometimes. But my worksharp field sherpener with diamonds and strops works fine. Anyways, i thought my angle was my problem on ceramic so i used my dmt angle guide. Still no edge. Like it kinda cuts paper but not… sharp. My theories are try one direction only, and now maybe im pushing down too hard and the edge is breaking?

Micro fractures along the edge are entirely possible when sharpening ceramic, I would recommend a light touch and if you still don’t see any screaming sharp results then try a convex grind like Virtuovice did here; https://www.youtube.com/watch?v=ub76qYaaV2Q

Let me know how it works out.

Four or five years ago, I decided I wanted to test drive some ceramic knives. I use knives in the kitchen, shop & office. I’ve made knives and any number of different cutting devices from raw steel over my 50+ years of carpentry, building custon cars and creating all sorts of things in my machine and wood shops.

I went to eBay and found a 5.00 ceramic knife with a 3-4″ blade and bought two; one to abuse in the shop and one to abuse in my office. I also bought a ~10.oo blue kitchen paring/utility knife w a 4″ blade and sheath and a 5″ bladed green one + sheath made by the same company. The second one cost me ~ 13.00.

The two black knives were made by a different company than the blue & green ones. They have been amazing. They were razor sharp when I got them and still are after ALL sorts of abuse. I have done everything to them except use them as screwdrivers or other obviously dumb things involving torsion or prying. They have performed and performed. To get as equally good blades in steel alloy would have cost me at least 2 or 3 x’s as much and would have needed sharpening, ( try cutting thin sheet aluaminum or brass with a steel,alloy knife as see if you’re not sharpening it.

As far as the kitchen, the blue knife is my go to knife. I slices breads or tomatoes, even flaky crossaints as well now as the first time, and it has seen plenty of repetitive machine gun chatter on a cutting board.

The green knife is an enigma, though. My wife left for a job on the opposite coast from our home shortly before I bought these knives, and I sent the green one to her after raving about the black and blue ones. She loves sharp knives, (especially when I sharpen them). She has been less than impressed with the knife.

When I started coming out for three month shifts on the right coast, I was disappointed with the knife, as well. It SEEMS to have an edge, but it is a turd.

I just picked up a small 5 stone DMT machinist’s and toolmakers set from MSC Direct, where she works, (guys, it is truly heaven when your wife goes to work for one of the world’s largest industrial suppliers and I can stock my shop at employee pricing!), and about to go at saving the ‘expensive’ ceramic knife I bought.

I would think it will be reborne as a great knife, as well.

If you wanna try ceramic, buy some cheap ones like I did and give them a whirl. I spent what, about 35.00 for four, and three of them have been fantastic. anot bad cnsidering the first time I looked at ceramic knives in about 1995, a paring knife was 115.00 and a 7-8 kitchen knife was nearly 300.00+ and neither one had a sheath.

I am glad to hear you had some positive experiences with ceramic, sadly I can’t echo the same.

Ain’t gonna argue how sharp they can get though. Definitely a scary edge.

It turns out my memory of where I got the two small ceramic knives I have so delightfully abused was inaccurate. I actually got them at… Harbor Freight!

If you want to read the tale of how I figured this out, and what the perfect use of ceramic knives is, as I discovered, in the process of figuring out I had bought the knives at HF, read the comment I just posted in reply to a note from X. The blog URL is http://morethanjustsurviving.com/knife-myths/#comment-160657, and if the tech gods are feeling generous, it might take you right to my April 17, 16 post. If not, you know have the date, as well.

So, if you wanna give a ceramic or three a whirl, the prices at HF have dropped about 50% on the two larger knives they sell, and a bit less on the small one. Get a 20%off coupon from your favorite AARP member and get even a better price, unless they are lumped in with welders and are not eligible. (We AARP members get two coupons a month, one in each of the AARP pubs, besides it gives all you kids a reason to call Mom/Dad/Grandparents!)

If you want/need a sharp point on one of the knives, look through the inventory and don’t just grab the one at the front. The two small knives I have don’t have sharp points and I have wished they did a few times. I figured out the QC on the points of these knives is about what you might expect when I bought a couple more, recently, but that’s all I’m gonna say, or I’ll blow the punch line of the ‘5 Myth’ post I just referred you to!

I wonder if Harbor Freight exists in the UK…*checks* sadly, no. :( I will be in North America early next year for a while so I will see about these.

Have you thought about using a coarse diamond stone to put a point on these ceramic knives?

Actually, you can buy some fair to middlin’ diamond sharpeners at HF also, I use the square 4 grit version fastened to a genuine plastic block and housed in the genuine plastic storage container, all for under 10 bucks. The grits include 200, 300, 400, and 600, not very fine grits but they will wear down if you are trying to sharpen anything steel with them. I use diamond sharpener blocks/”stones” for ceramic knife sharpening and for flattening my Japanese water stones. Period. Steel seems to extract the diamonds from the steel plate they are affixed to in no time at all and I have heard that the diamond sharpeners are so hard, they bury themselves, grit by grit, into the very steel they are being used to sharpen until they are broken down or have been fractured and broken the bonding agent which holds them to the base steel plate.

I own 2 DMT diamond plates and both of them went “dull” within a month of using them on reshaping the bevel of knife blades. I still use both of them on my Japanese whetstones but the damage has been done and I have learned a valuable lesson on a couple of levels.

Regardless of price, HF 4 grit thin diamond plates on the square plastic block (less than 10 bucks total) or the high dollar DMT 3/8″ thick solid steel plate in 120 grit to 1500 grit ranges each,(upwards of 80 bucks per plate), if you use the diamond plates for ceramic sharpening, you won’t have as much breakdown of the industrial diamonds as you would using them to rebevel or sharpen anything steel. It may seen crazy but I can vouch, first hand, at having the diamond surface of these hones go “flat” on me in no time at all.

Hi, following on Twitter and now your blog.. Good posts!

Welcome, & thanks for stopping by with a comment! :) Glad you like our posts.